China and the United States are not likely to hug and kiss each other and end their present trade war, at least not as long as Donald Trump remains as the president. Like it or not, it’s a matter of time before the trade war goes full-blown. The world’s two biggest economic powers are digging in – preparing and readying for a tough and long period of deteriorating war.

President Donald Trump’s blacklisting of Huawei has essentially left President Xi Jinping with no choice but to call the 1.4-billion mainland Chinese to brace themselves for a “new Long March”. It was a rally for the Chinese people not to yield to foreign bullying and assault. In response, Trump announced US$16 billion aid program for farmers caught in the crossfire, a sign of prolongingtrade war.

The Chinese word for “crisis” is frequently invoked in Western motivational talks as being composed of two Chinese characters respectively signifying “danger” and “opportunity”. Hence, there have been talks and analysis of the implications or the impacts of the US-China trade war to the world. In short, which nation(s) will benefit from the ongoing trade war?

That’s a tricky question. In general, every nation in the world will benefit from the trade war. The United Nations says the European Union is set to be the biggest winner of the trade war. The organization estimated that European companies are likely to capture about US$70 billion in trade – about US$50 billion in Chinese exports and US$20 billion in US exports.

The United Nations Conference on Trade and Development (UNCTAD) says other nations like Japan, Mexico and Canada will each likely to capture more than US$20 billion in trade. In Asia, however, the four “Asian Tigers” – Hong Kong, Singapore, Taiwan and South Korea – are expected to enjoy the least benefits from the spillover of the trade war.

Again, everything depends on which products or produce that the U.S. and China plan to punish each other. Anything from the Boeing commercial plane to red wines to clothing to smartphone covers could be targeted. The trade war is pushing the business cost up the roof, forcing companies to move their production or supply chains out of mainland China.

Asia’s low-cost manufacturing hubs seem like attractive destinations, especially Vietnam, Thailand, Cambodia, Indonesia, Bangladesh and Malaysia. Even India is a sexy manufacturing hub. According to a survey by Deloitte, the “Mighty Five” or MITI-V, consisting of Malaysia, India, Thailand, Indonesia, and Vietnam, will take over as the “new China”.

In reality, China is no longer a magnet for low-cost manufacturing. The Middle Kingdom has quietly graduated into medium to high-tech manufacturing as its labour costs have steadily risen. Manufacturing goods in China on average are only 4% cheaper than in the U.S., largely due to yearly average manufacturing wages which have been up by 80% since 2010.

Huawei aside, China has been producing electric vehicles, flying cars, solar power, satellites, super computers, micro-processors, drones and robotics, fighter jets, commercial planes, spacecraft, destroyers, facial-recognition technology, artificial intelligence, high-speed rail, 5G technology, anti-satellite weapons, aircraft-carrier and whatnot.

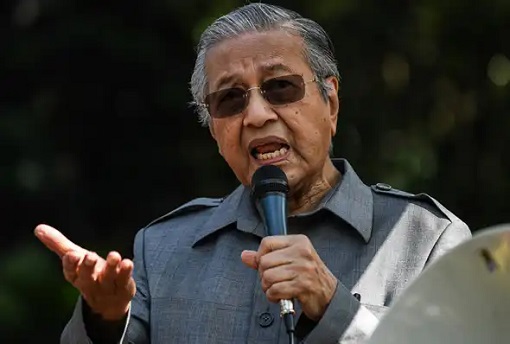

Among the “Mighty Five”, one country stands out magnificently in the manufacturing sector – Malaysia. The 1980s was the booming period for the manufacturing industry in Malaysia as Japanese companies started to build their factories in the country. That was when Prime Minister Mahathir Mohamad adopted the infamous “Look East Policy”.

Like it or not, it was both humiliating and exciting when the same Mahathir, who becomes premier again for the second time after the last May general election, revives the “Look East Policy” again during his visit to Tokyo last June. It was humiliating because it was found that the country is still stuck in the 1980s mentality, never graduated from the low-cost manufacturing sector.

But it was also exciting as it provides the second chance for Mahathir to correct his past mistake – creation of artificially lower salaries to maintain competitiveness in the manufacturing industry. Even in medium-tech manufacturing, national car Proton’s rapid penetration in the domestic market was based largely on price competitiveness artificially created by government policy.

Despite artificial low wages, Malaysia continued losing its competitiveness when even local businessmen started flocking to China – preferred to invest in the mainland because there were more opportunities and they don’t find it easy to do business in Malaysia – thanks to discrimination policy like the NEP (New Economic Policy), which subsequently restructured as NDP (national development policy).

The NEP, designed to uplift the ethnic Malay, but soon became a means for UMNO to cement political support and an enrichment program for a selected few, was responsible for worsening income inequality even within the Malays themselves. To outdo low-cost manpower in China and India, the previous government took the shortcut of importing cheaper migrant workers from Indonesia and Bangladesh.

Last year, when China automaker Geely, the owner of Proton by virtue of its 49.9% stake, introduced meritocracy culture into the local car manufacturer, Pekema (Malaysian Association of Malay Vehicle Importers and Traders) had played the race card – accusing the Geely Chinese’ new business direction of introducing 4S centres as an attempt to kill off ethnic-Malay distributors.

Like manufacturing assembly lines, the NEP policy continues producing not only uncompetitive human resources, especially among the majority ethnic Malay, but also generations of lazy and untrustworthy race. Hey, that was not what I said. That was what PM Mahathir said – again and again. Worst, the Malays, believe they are supreme, continue demanding for handouts.

Yesterday, Mokhtar Samad, the chairman of the Malaysian Bumiputera Contractors Association, shamelessly demanded a special quota of at least 20% of civil works in the East Coast Rail Link (ECRL) project, the controversial mega project which was finally given the green light after the initial cost was reduced significantly by RM21.5 billion to RM44 billion.

Mr. Mokhtar, a politician who is also the UMNO Chief of Bandar Tun Razak, has claimed that 42,000 Bumiputera (son of the soil) contractors have the expertise and skills to be involved in the project. Yet, amusingly, he also said that without the special quota, the Bumiputera contractors would find it difficult to competewith other local companies – obviously a self-contradictory statement.

Adding salt into injury, the quota system in tertiary education makes the unemployment market worse. The recent fiasco on quota in the pre-university matriculation program has again reopened the embarrassing fact that despite given the “back door” to enter university, the majority of the Malays found themselves to be “unemployable” despite being the proud owner of a piece of degree.

Make no mistake. Although the US-China trade war has seen increasing number of foreign manufacturers moving factories out of China, they did not go back to America. Surprisingly, those manufacturers that move to a “second China” – in Southeast Asia – are actually Chinese companies. Yes, the Chinese creatively and cleverly move elsewhere to create a false impression that Trump is winning.

The billion dollar question is, will China manufacturers move to Malaysia? Sadly, while Asean (ten countries in Southeast Asia) remains the preferred destination for China manufacturers looking to relocate their production facilities as a result of the trade war and escalating business cost, Malaysia is not the popular destination.

According to a survey done by Standard Chartered in 2017, Cambodia and Vietnam were the most favoured destinations in the region. Heck, even Myanmar and Indonesia were more attractive than Malaysia. Cost-efficient labour supply, supportive investment policies, attractive tax incentives and free trade agreement were among the reasons.

Vietnam, arguably is the most preferred choice due to its close proximity to China as well as good infrastructure and stable political environment, not to mention the “wages are half that of China”. Vietnam has labour forces as huge as 57.5 million. Production workers in Vietnam are paid an average of US$250 (£197; RM1,046) a month. Are the Malaysian unemployable graduates willing to work with such a salary?

Malaysia is nowhere here or there. The country is no longer competitive in terms of low-cost labour. But at the same time, the country has not moved up the value chain. The clearest proof emerges today when Rafidah Aziz, former Minister of International Trade and Industry from 1987 to 2008, admits that the old education format can no longer cope with the demands of Industry 4.0.

She should not have thrown such jargon or brain-challenge statements. If the unemployable graduates have no idea what “meritocracy” is, chances are they are equally clueless about “Industry 4.0”. The buzzword means “smart factory” or “Fourth Industrial Revolution” – involving connectivity between the digital world with biological systems like humans through the internet.

The technology of Industry 4.0 comprises Artificial Intelligence (AI) to learn from its surroundings and Cloud Computing technology for storing and processing data. Others include Internet of Things (IoT) that connects a device to smart senses using an internet connection, cyber security that protects data and minimises risks and 3D printing that facilitates the production of prototypes.

Clearly, Malaysian education system, especially the national schools which have been transformed into religious schools as revealed by PM Mahathir last December, needs a major revolution from the primary level. Instead of obsessing with religious books, students need to be taught how to develop technologies using codes and algorithms to produce highly-skilled manpower for the future job market.

Malaysian’s lower skilled labour coupled with higher wages are definitely not the selling point in attracting Chinese investors in low-cost manufacturing. In the high-tech manufacturing, the local graduates, besides lacking proficiency in English and Mandarin as well as ICT related skills, have been taking the easier humanities or religious studies – which have very little relevance to business and industry requirements.

FINANCE TWITTER

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.